– What is the essence of your research?

Traditional die-cutting presses perform only basic operations: cutting and creasing cardboard layouts. However, the modern packaging market demands more, such as high-quality embossing and flexibility in setup.

We identified two main objectives: to ensure prolonged contact between the die-cutting form tools and the cardboard for better finishing quality, and to reduce the load on the drive, thereby improving machine lifespan and energy efficiency.

One of our latest solutions involves a combined wedge mechanism with an additional crankshaft. It enabled a 12% increase in contact time and reduced peak accelerations by more than three times.

– What methods do you use?

I combine classical mechanical engineering with programming. First, I create mathematical models, then computer programs for calculations and quick construction of 3D models in SolidWorks.

For virtual analysis, I developed several Python-based programs that automatically generate parametric 3D models and simulate motion, which significantly speeds up the analysis process.

Another key approach is the innovative application of similarity theory in engineering. We use the displacement of the pressing plate as the "unit" parameter, and based on this, we perform numerous mechanism calculations. It allows for the effective comparison of different designs and data, as well as the analysis of kinematic parameters and force loads. When necessary, we can scale the model to real sizes and immediately perform calculations for a specific press format. This approach significantly simplifies and speeds up the research process.

Additionally, in our department, we design and build experimental test stands using strain gauges to measure force loads. It helps obtain absolute values of the studied parameters in real-time and assess the impact of factors like cardboard thickness, fiber orientation in the material, and equipment speed modes.

– How vital are experimental and virtual studies in your work?

For us, these are two complementary directions. Virtual studies in CAD systems, combined with programmed computational models, enable us to evaluate the kinematic and force parameters of mechanisms quickly, compare different design options, and determine the optimal solutions. In such models, we can see graphs of velocities, accelerations, and forces at any moment of the cycle, which is very convenient for comparing new and existing mechanisms.

But no virtual model can replace an experiment. Only bench tests provide an accurate understanding of the real behavior of cardboard. We conducted a series of tests with different cardboard thicknesses (0.3–0.7 mm), fiber orientations, and press operating speeds. For example, we found that when the crankshaft speed was increased fourfold, the torque on the shaft decreased by 13–30%.

Thus, virtual studies are essential at the design stage and provide quick evaluation. At the same time, experiments confirm the results and allow us to account for factors that cannot be simulated (such as humidity or material defects). We always combine both approaches.

– Which of your results do you find most interesting?

Firstly, the redesign of the press's pressure plate. We proposed a sectional structure, which significantly reduced the press's peak load, ensured energy-efficient operation, and notably decreased metal consumption.

Secondly, combined drives: they provide uniform movement of the pressure plate, reduce loads, and remain simple in construction.

Third, the proposed presses ensure high-quality execution of finishing operations for packaging. It includes embossing of packaging materials and precise production of layouts.

Finally, our advancements in digital modeling and drive lifespan calculation enable the prediction of machine durability, a crucial factor in production. One standout result is the prediction of press designs across a wide range of formats.

– You mentioned combined drives. What makes them unique?

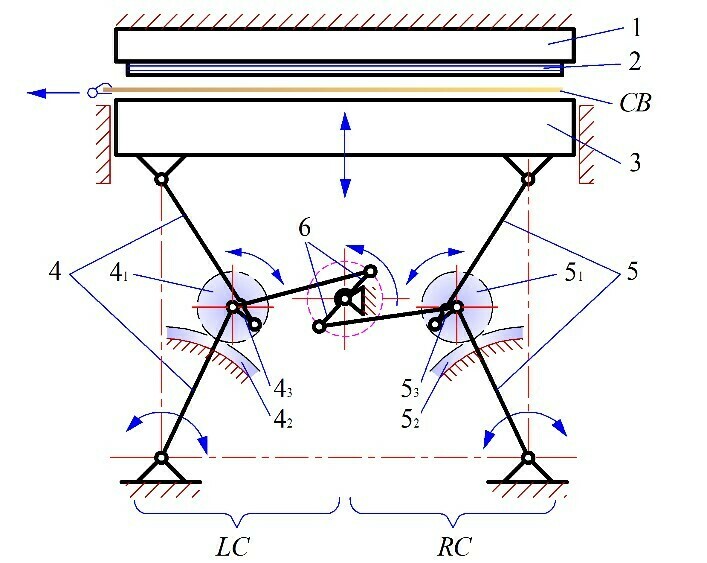

Classical wedging mechanisms tend to move with some oscillations and operate asymmetrically. It reduces the performance characteristics of the press. To address this issue, we proposed a double-slider wedging mechanism, which ensures uniform plate movement, reduces peak accelerations, and is structurally simpler.

We also developed a mechanism that uses two double-wedging contours operating synchronously, as well as a wedging mechanism with an additional driven crank and gear transmission. Due to this modernization, it is possible to reduce inertial loads significantly, extend the contact between the tools and the cardboard, and lower peak loads on the drive.

Such combined solutions not only improve the technological process (especially cold embossing) but also reduce energy consumption and extend the service life of presses.

Kinematic diagram of a die-cutting press with modernized wedge mechanisms on the left and right sides of the pressure plate drive

– Your articles are published in international journals. How do you assess the significance of this communication?

For me, this is a matter of principle. Publications in international journals are not only confirmation of scientific novelty but also integration of Ukrainian developments into the global engineering community. Our latest articles published in the Australian Journal of Mechanical Engineering and the Academic Journal of Manufacturing Engineering have already attracted interest from colleagues in Europe and Asia.

At present, we also have several articles under review for publication in international journals indexed in Scopus. I always prefer such journals, since they guarantee high-quality peer review, global recognition, and greater impact on the field.

– What is the significance of this research for the industry?

The cardboard packaging market is changing rapidly, prompting manufacturers to adopt modern equipment. It must deliver both high product quality and meet durability and cost-efficiency standards.

Our developments are specifically designed to address these technical challenges.

A modern die-cutting press is no longer just a machine for cutting and creasing cardboard layouts — it is also a tool for high-quality finishing of cardboard products.

– What are your future plans?

The next step is to develop software for rapid design analysis and create digital twins of die-cutting presses. It will enable the integration of experimental and computational data into a unified system, opening up new possibilities for the industry.

Conclusion

Vitalii Vlakh's work demonstrates that even in the traditional field of packaging equipment, there is room for innovation. Extended tool-to-cardboard contact, reduced peak drive loads, a sectional pressure plate structure, and the application of similarity theory all form a new quality standard in the development of modern die-cutting equipment.

Передплата на журнал Print+

Передплата на журнал Print+ Ефективні рекламні можливості у Соціальній мережі поліграфістів

Ефективні рекламні можливості у Соціальній мережі поліграфістів Наші послуги для поліграфістів

Наші послуги для поліграфістів Передплата на Print+

Передплата на Print+ "Друкуймо разом" у Telegram

"Друкуймо разом" у Telegram